We concentrate on engineering heavy-duty clutches at Yichun Marke Auto Parts Manufacturing Co., Ltd. because they are tested for use in construction machinery. After starting in 2014, we have created custom solutions to help excavators, loaders, bulldozers and other construction machines handle their unique challenges.

Key Requirements for Construction Vehicle Clutches

Systems with clutches are required for construction tools that can cope with:

Extreme pressures on the enemy’s vehicles

All pressure plates are rated for up to 3,500 Nm clamp force

Connections made using reinforced splines

Materials composed of different layers

Difficult Environment

Products built to resist dust and debris

Bearing systems designed to work in wet environments

Corrosion-protected components

Many times of Stopping and Starting

Better ways to share heat with the environment

Hard wearing friction materials

The heavy-duty diaphragm springs

Our Construction-Optimized Clutch Solutions

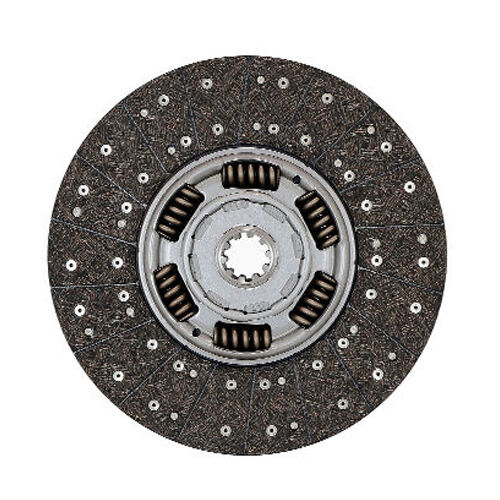

1. Heavy-Duty Single Plate Clutches

Are used in: Medium-duty loaders and backhoes

Features:

Two-thirds thicker friction surfaces

Organic pressure plate design

Anti-contamination seals

2. Dual Clutch Systems

Large tonnage machines find a home in the earthmoving industry and are used in mining

Features:

Working toward involvement for better results

Channels that are independent from each other

The dual-mass flywheel is compatible with this car

3. Ceramic Composite Clutches

High-performance equipment for compacting materials

Features:

It is able to handle temperatures that are 40% higher

More stable performance when it’s warm

Longer time between oil changes

Technical Differentiators

Why our construction clutches are different:

Material Science:

Unique recipes for friction material

Fabricated forged alloy steel components

Rust-protective coatings made for the military

Engineering Features:

Systems that control shock during an accident

Making sure your rotation is between 14 g-cm and 16 g-cm

Precisely made surfaces that fit together

Durability Enhancements:

Services have twice the expected lifespan

Up to double the dust resistance when compared to past models

Systems that do not require maintenance and can adjust themselves

Selection Considerations

While selecting a clutch for your machines on construction sites:

Operating Environment

Temperature tolerance of hot and cold conditions

Making certain there are no contaminants

Corrosion resistance

Operation Time Requirements

Why Choose Yichun Marke?

10+ years of construction equipment specialization

Custom engineering services available

Complete testing including:

1,000 hour simulated site testing

Mud immersion validation

Shock load durability testing

Get in touch with our engineering department now to find the right clutch for your needs. You can rely on us to find the right solution for your construction equipment - not having it up and running isn’t a choice you can make on your job site.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

SW

SW

GA

GA

HY

HY

KK

KK