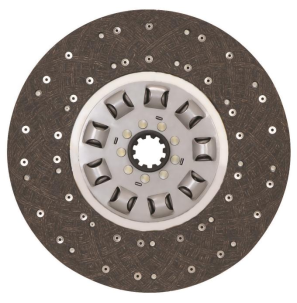

Construction vehicles work in one of the harshest environments ever. The range of machines, such as excavators, bulldozers, and heavy-duty haul trucks, requires the component design in order to face endless power and continuous strain combined with difficult conditions. Mark engineers clutches to the extreme to satisfy these severe requirements. When choosing a clutch to fit your construction machines, pay particular attention to the following most important performance parameters based on the fundamental engineering principles:

Exceptional Thermal Management Capability

The main opponents of the clutch performance and its durability are heat. Building activities such as heavy pulling, frequent start and stop operations and working along steep slopes produce lots and lots of friction heat. A clutch has to very quickly remove this heat, otherwise glazing, warping and disaster can happen. Mark clutches are built with high technologies friction and cooling systems to withstand long-lasting high temperatures without reducing the engagement feel and maximum torque. Identify designs with the credentials of handling high thermal loads under sustained heavy load conditions.

Robust Torque Capacity and Driveline Protection

Earth-moving and rock-moving construction vehicles provide huge torque. The clutch, at the maximum overload, should hold onto this engine power without slipping, but, should be a safety guard. Another major spec is that it is shock amounts taking up shock loads and reducing driveline vibrations inherent in rough business. Mark diagonals are provided to safeguard transmissions, transfer cases and axles against the destructive nature of unexpected, high-intensity torque increments and jerked engagement, greatly minimized danger of the expensive downstream component failure.

Uncompromising Durability and Contamination Resistance

The always present partners on the building sites are dust, mud and water, and even debris. Clutches have a very heavy duty and need to resist ingress of contamination that increases the rate of wear. Pay more attention to the clutches made of high quality materials and clutches with sealed construction, which are closed to abrasive particles and unable to damage the friction surfaces or the mechanisms inside. Mark has tough engineering with an eye toward a long service life in a dirty environment, reducing unplanned out, and maintenance expense by a superior contamination resistance and wear.

Precise Application Fit and Operator Control

Vehicles used in constructions and the tasks they carry are not all alike. The perfect clutch should be coupled with the power that was produced by the specific vehicle, its weight, normal duty cycle and the type of transmission utilized. It ought to give comfortable engagement (predictable), operator comfort and precise control when a light operation is required yet provide good lock-up when brute force must be applied. Mark also focuses on the development of clutches that offer users adequate control and adequate power transmission that suits the individual needs of various construction projects.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

SW

SW

GA

GA

HY

HY

KK

KK